How Handmade Rugs Are Made

Handmade rugs result from a long, highly specialized process involving multiple skilled professionals, each responsible for a specific stage of creation. Unlike factory-made carpets, a handmade rug is not produced by a single machine or by a single individual. Instead, it evolves step by step, often over many months, through careful planning, preparation, and execution.

Understanding how handmade rugs are made requires looking beyond the loom itself. The process begins long before the first knot is tied and continues well after the final row of weaving is completed. Every stage—from artistic design to loom preparation, weaving, and finishing—directly affects the rug’s quality, structure, and longevity.

The First Step: Artistic Design and Concept Creation

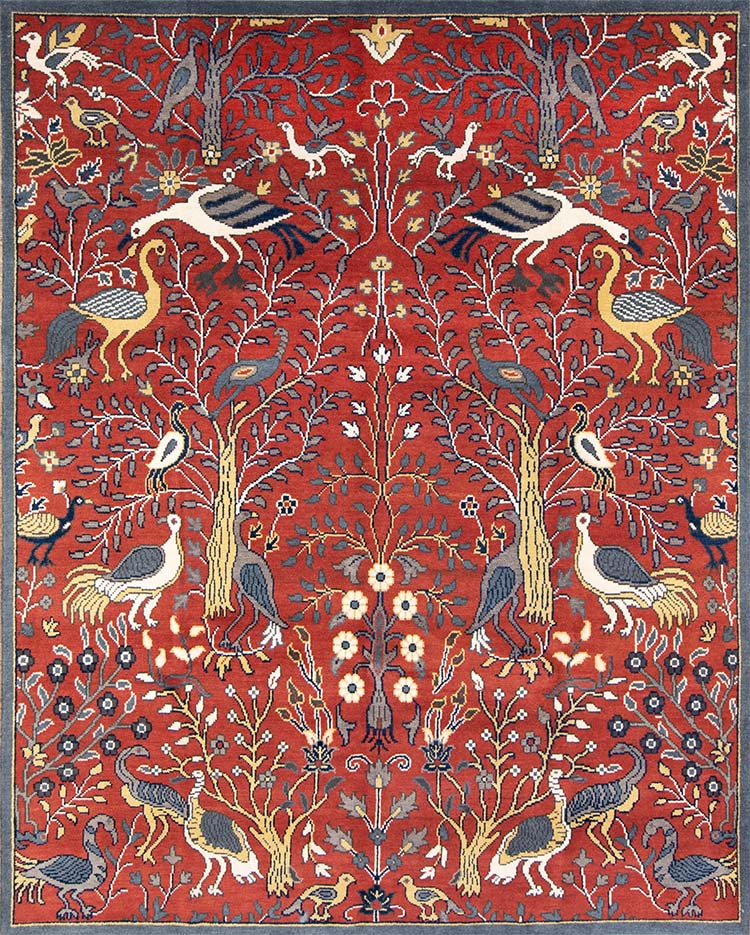

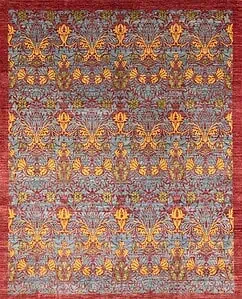

Every handmade rug begins as an idea. This idea is developed by an artist or designer who understands balance, symmetry, proportion, and rhythm. The designer is responsible for determining the overall visual identity of the rug, including pattern layout, spacing, and decorative flow.

At this stage, the focus is not on materials or weaving techniques, but on composition. The designer considers:

-

How motifs repeat or evolve across the surface

-

How negative space is used

-

How borders interact with the central field

-

How visual weight is distributed

The design must be both functional and beautiful. A design that looks appealing on paper must also translate clearly into thousands—or millions—of individual knots.

Transferring the Design to Checkered Paper

Once the design is finalized, it is transferred onto checkered (gridded) paper, often called a rug map or cartoon. Each square on the paper represents a single knot. This transformation is critical because it converts artistic expression into a technical blueprint that weavers can follow precisely.

At this stage, the designer’s role overlaps with color planning. The artist assigns specific colors to each section of the grid, carefully considering contrast, transitions, and visual harmony. The map shows:

-

Exact knot placement

-

Color changes

-

Pattern alignment

-

Repetition structure

Dividing the Design for Weavers

Large rugs often involve multiple weavers working simultaneously. To manage this, the completed rug map is divided into smaller segments, each corresponding to a section of the rug.

These segments are placed directly in front of the weavers on the loom. The weaver does not improvise or alter the design; their task is to translate the map into knots with absolute accuracy. Precision at this stage is essential, as even small deviations can disrupt the overall pattern.

This segmented approach ensures:

-

Consistency across the rug

-

Efficient workflow

-

Uniform tension and alignment

Material Selection: Choosing and Preparing the Wool

While the design phase is underway, the rug master focuses on materials. Wool selection is one of the most critical decisions in determining the final quality of the rug.

The thickness and fineness of the wool are chosen based on:

-

The complexity of the design

-

Desired knot density

-

Intended texture of the pile

Finer wool allows for more detailed patterns, while thicker wool creates a more robust and textured surface. The master orders specific wool types and arranges for them to be spun to the required thickness.

Although dyeing is a separate craft, color preparation happens concurrently so that materials are ready when weaving begins.

How Handmade Rugs Are Made by Preparing the Foundation (Warp and Weft)

Before any weaving can start, the loom must be prepared. This task is handled by a specialist who is responsible for laying the foundation of the rug.

The foundation consists of:

-

Warp threads (vertical)

-

Weft threads (horizontal)

The spacing, tension, and material of the warp and weft are determined by:

-

Rug size

-

Knot density

-

Desired durability

-

Overall fineness

A tightly prepared foundation allows the rug to maintain its shape and ensures even wear over time. Errors at this stage cannot be corrected later, which is why loom preparation is entrusted only to experienced professionals.

Assembling the Weaving Team

Once the foundation is ready, the master selects the weavers. Weaving handmade rugs requires physical endurance, concentration, and technical skill. Each weaver must:

-

Read the rug map accurately

-

Maintain consistent knot tension

-

Align rows precisely

-

Work at a steady, controlled pace

The weavers sit at the loom, facing the design map, knot by knot, building the rug from the bottom upward.

The Weaving Process: Knot by Knot Construction

The core of how handmade rugs are made lies in the knotting process. Each knot is tied individually around the warp threads using a specific knot type. After completing a row of knots, the weaver inserts weft threads and compresses them to lock the knots in place.

This sequence is repeated continuously:

-

Tie knots

-

Insert weft

-

Compress

-

Trim excess wool

-

Move to the next row

Depending on size and complexity, a single rug may require months or even years to complete. Learn more about technical knot structures.

Regional Design Logic Without Regional Focus

Although this blog does not focus on specific rug regions, it is important to understand that design logic and color combinations are tied to where a rug is woven.

Design traditions influence:

-

Motif structure

-

Pattern density

-

Symmetry rules

-

Color balance

Weavers and designers are trained within these traditions, and their visual language reflects centuries of accumulated knowledge. Even when not naming regions, these influences shape every handmade rug.

Monitoring Quality During Weaving

Throughout the weaving process, the master regularly inspects the rug. This includes:

-

Checking knot density

-

Ensuring pattern accuracy

-

Verifying color placement

-

Monitoring foundation tension

Corrections are made immediately when necessary. Delaying adjustments can result in structural or visual flaws that cannot be fixed later.

Completing the Weaving

When the final row is finished, the rug is carefully cut from the loom. At this point, the rug is still incomplete. The pile height may be uneven, and the fibers are stiff from tension. This leads to the next critical stage.

Finishing the Rug

Finishing is a multi-step process that transforms the woven rug into its final form. It includes:

-

Trimming the pile to achieve uniform height

-

Washing to soften fibers and remove residues

-

Stretching to correct shape and alignment

-

Drying under controlled conditions

Improper finishing can permanently damage a rug, even if the weaving is perfect. Skilled finishing brings clarity to the design and enhances durability.

Why Handmade Rugs Age Gradually

Because handmade rugs are constructed from natural fibers under tension, they respond slowly to their environment. Changes in temperature, humidity, and placement affect them over time. This is why proper care and placement matter. When damage does occur, professional Rug Repair and Restoration may be required to preserve the rug’s structure.

Understanding Handmade Rugs as Functional Craft

Knowing how handmade rugs are made changes how they are valued. Each rug represents:

-

Artistic planning

-

Technical mapping

-

Material science

-

Skilled labor

-

Time-intensive execution

Handmade rugs are not simply decorative items. They are functional works of craftsmanship designed to last for generations when properly cared for. Here is a broader conservation perspective to study.